Experimental Laboratory

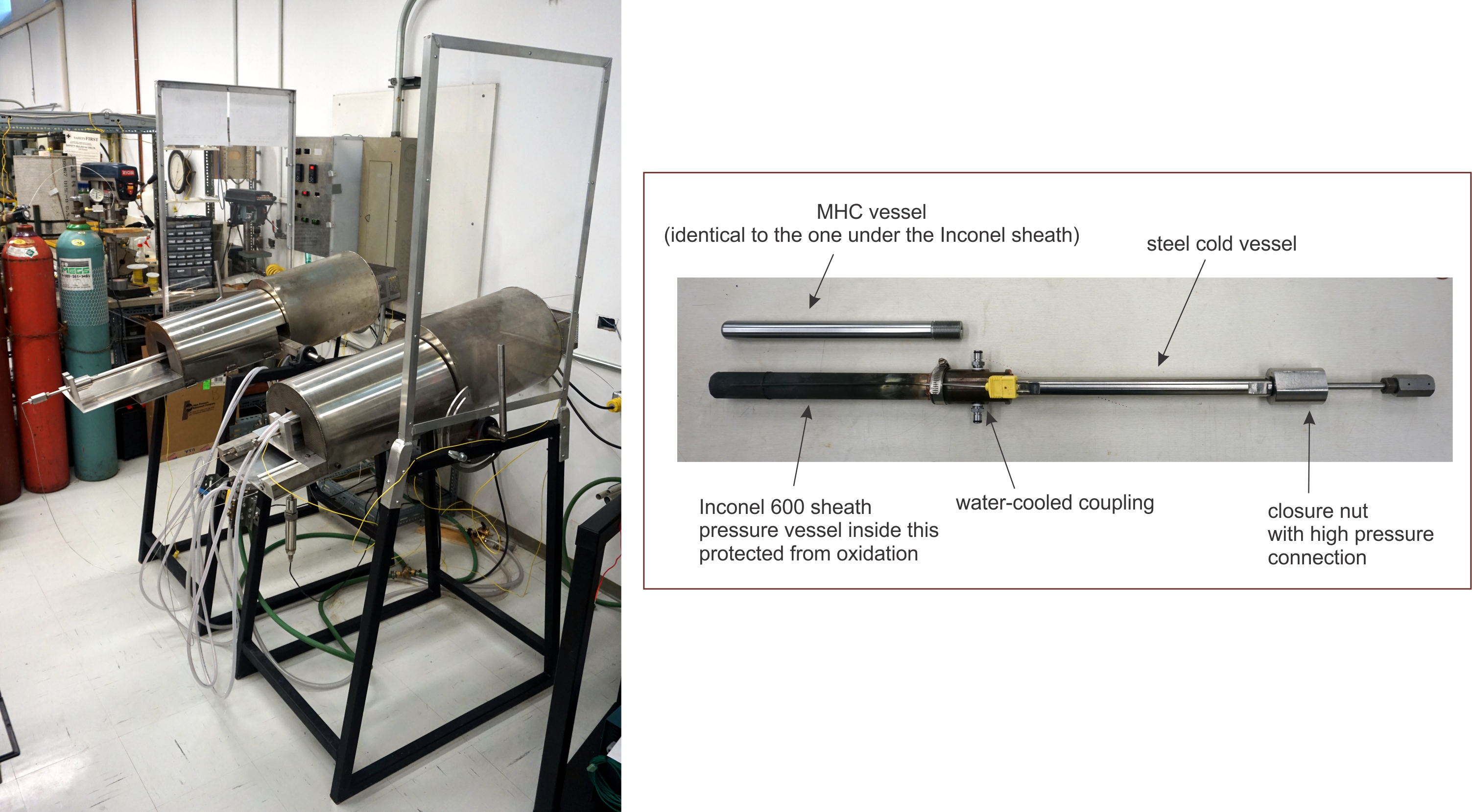

Molybdenum Hafnium-Carbide pressure vessel assemblies

The pressure vessel assembly is suspended together with the furnace on a rotating axis. Experiments can be run in 10 degrees tilted (as shown) or vertical position. The vessel can be removed from the furnace while being shielded by 2 mm thick stainless steel. The pressure is monitored by factory-calibrated digital pressure transducers on each assembly and an analogue strain gauge on the main line.

Currently, two pressure vessel assemblies are operational and the third one is under construction.

Some of the highlights are:

- Achievable pressure and temperature up to 300 MPa and 1150 oC

- In-house built furnaces designed to minimize temperature gradients (≤12 oC over 2 cm capsule length)

- The furnace-vessel assembly is on a rotating axis allowing rapid drop quenching as well as in situ fracturing of quartz during the experiment for fluid inclusion synthesis

- Water-cooled coupling to a cold steel vessel extension allowing for instant quenching

- Set up for admixing precise amounts of hydrogen into the argon pressure medium to impose desired fO2 or prolong the lifetime of redox buffers (200 MPa pressure limit on this assembly)

- Pressure and temperature logging

- Safe removal of the hot vessel from the furnace after quenching allowing for short wait time between experiments

- Robust, pressure leak-free design

Other experimental petrology equipment

In addition, we have access to Inconel 917 and Rene41 cold-seal pressure vessels, two piston cylinder apparatuses, high temperature box furnaces and two gas mixing furnaces in Prof. James Brenan’s experimental laboratory and an induction furnace in Prof. Grant Henderson’s laboratory.